Yikes! It's been ten months since my last post. Unfortunately, my ops session last March turned out to be a COVID spreading event, with most of my guest operators, and then several of our wives, coming down with the disease. And after that, 2022 just got worse and worse. So all in all, I didn't get much model railroading done during the year.

However, with Christmas, New Year and then Australia Day festivities out of the way, I've resumed activity on the layout.

Installing push-rods to operate switches

First off, I modified six ME switches that I installed at Dougherty way back in 2005, and then installed fascia mounted push-rods to operate them. I don't know why I didn't make provision for the push-rods when I installed the switches, but for the past 17 years we've had to slide the point rails across using our fingers. This is how the switches and their push-rods look (well, some of them, anyway.)

|

Three of the six switches before they were modified. The throw-bar is very short and narrow,

making it difficult to install a wire to operate it. |

|

Two of the switches after modification. I replaced the throw-bar with a longer and wider PCB tie.

I also cut gaps in the closure rails and then soldered power feeders so that they bridged each

closure rail and its adjacent stock rail. Then I powered the frog using a DPDT slide switch mounted under the layout. |

|

| This is how the switches and their control knobs look from the operating aisle. |

First operating session for 2023

Yesterday the GC&SF hosted its first operating session for the year. I was a bit nervous about how it would go as most of the trains had done very little running since the session way back in last March. Eight guest operators came over to run trains, and while I got stressed out far more than usual, things went pretty well, and I think that all the guys enjoyed themselves.

Here are some photos from the day.

|

(L-R) Chris, Peter S. and Peter K. at Dougherty. Peter K. is operating the Ardmore local freight

that is switching cars on the track behind the depot. |

|

| Ooops ... something went wrong. |

|

As Peter K. rerails a car at Dougherty, Peter S. is operating the morning Pauls Valley local freight,

and switching cars at Davis. |

|

| John C. an the town switching job at Pauls Valley. Here he is uncoupling cars at the grain elevator |

|

John F. did a great job running the yard at Pauls Valley. In the background,

Derek is about to bring a through freight into the Pauls Valley arrival track. |

|

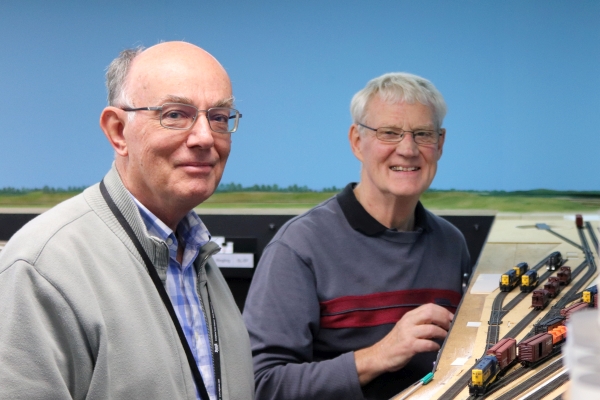

| (L-R) Me, John F. and John C. at Pauls Valley. |

|

Greg (in the background) and Bill teamed up to run the south-bound (morning) gravel train.

Here, they've just picked up loaded cars from Dolese at Big Canyon and are about to

couple them onto the cars they collected from Southern Rock at Dougherty. |

|

Greg must like running the gravel trains because here he is running the northbound (afternoon)

gravel train. |

|

| Derek at Davis with the afternoon local freight from Pauls Valley. |

|

| The train line up at the south staging yards prior to the start of the session. |

As I mentioned, I got a bit stressed out during the session as I tried to operate the yard at Ardmore as well as trouble-shoot problems. I hadn't taken into account that most of the crew members haven't operated the layout in almost a year and for some of them it was even longer. So the guys were all somewhat rusty on how to go about their 'work'.

Nevertheless, it was a good session and I enjoyed catching up with everybody again. Thank-you to all the crew members for coming oer to play trains.

Regards,

Ron